The longevity and performance of your tools are pivotal factors that impact the quality and efficiency of your work. One critical aspect of tool maintenance and optimization is trimming carbide-tipped bits. Proper trimming ensures that the cutting edges of your tools remain sharp and efficient, ultimately extending your lifespan and saving you time and money in the long run. This blog will explore the importance of trimming carbide tipped bits like a professional.

What are Carbide Tipped Bits?

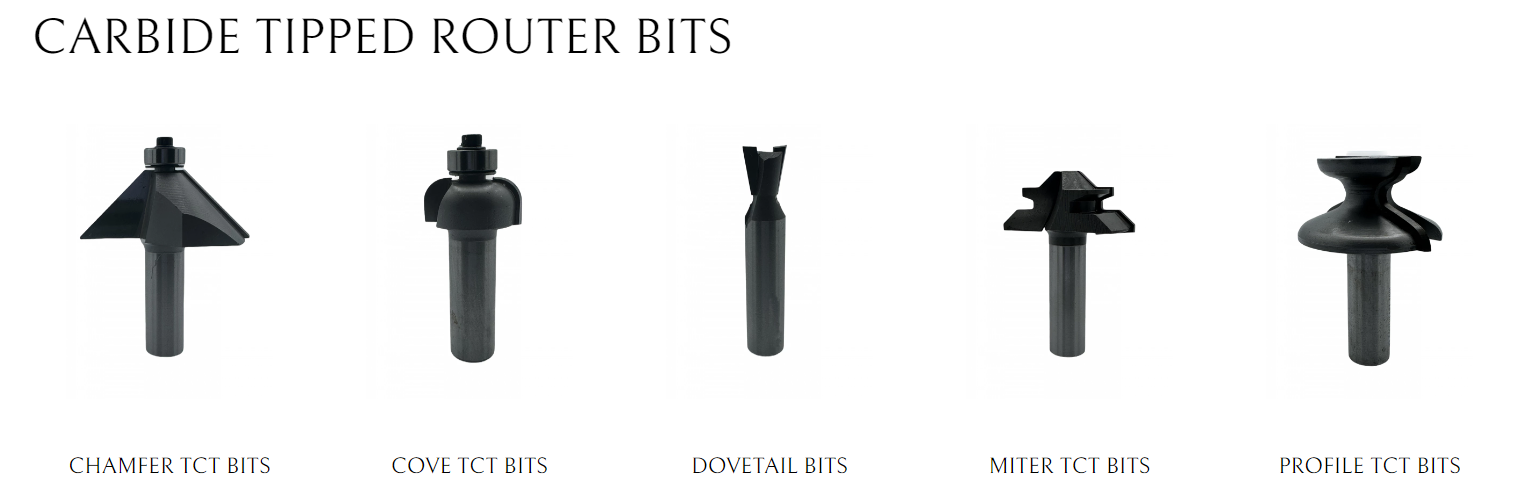

Carbide tipped bits are indispensable in various industries, including metalworking, woodworking, and machining. These tools are known for their durability and ability to withstand high-speed cutting. Still, their cutting edges can become dull or damaged over time due to the rigorous demands of machining. That’s where trimming comes into play.

Steps to Trim Carbide Tipped Bits Like a Pro

Here’s a step-by-step guide to trimming carbide tipped bits professionally:

1. Tool Inspection: Regularly inspect your carbide tipped bits for signs of wear, damage, or dullness. This inspection should be part of your routine maintenance. When you notice issues with your cutting edges, it’s time to trim.

2. Safety Precautions: Trimming carbide tipped bits requires safety measures and equipment. Wear safety goggles and other protective gear, and work to minimize exposure to dust and fumes.

3. Selecting the Right Trimming Method: There are various methods for trimming carbide tipped bits, including grinding, honing, and re-sharpening. The technique depends on factors like the type of tool and the extent of wear. Select the appropriate method for the task at hand.

4. Trimming Process: Once you’ve chosen the trimming method, follow a step-by-step process that involves positioning the tool correctly, adjusting angles, and employing techniques to achieve sharp and effective cutting edges. This process demands precision and skill.

Common Mistakes to Avoid

To achieve professional results while trimming carbide tipped bits, it’s crucial to avoid common mistakes:

- Inadequate Inspection: Failing to inspect your tools regularly can lead to the use of dull or damaged bits, negatively impacting the quality of your work.

- Lack of Safety Precautions: Trimming generates dust and heat, making safety precautions essential. Neglecting safety gear can lead to accidents or health risks.

- Choosing the Wrong Trimming Method: Using an inappropriate method for trimming can worsen the condition of the tool or lead to improper edge geometry.

Benefits of Professional Trimming

Professional trimming offers a range of advantages. These include:

● Extended Tool Life: Regular and professional trimming extends the life of your carbide tipped bits, reducing the frequency of tool replacements.

● Improved Machining Results: Properly trimmed bits produce better surface finishes, tighter tolerances, and enhanced efficiency in your machining operations.

● Cost Savings: By maximizing the lifespan of your tools and improving their performance, you reduce the overall cost of tool maintenance and replacement.

Conclusion

Properly trimming carbide tipped bits is an art that impacts the performance of your tools. By following the steps of professional trimming and avoiding mistakes, ensure your devices consistently produce high-quality results. Professional trim isn’t just about extending the life of your tools; it’s about enhancing the precision and efficiency of your machining operations. In an industry where accuracy and cost-effectiveness are paramount, trimming carbide tipped bits like a professional is your key to success.