Explore the comprehensive guide to CNC maintenance with KES Machine LLC in the USA. Unlock the secrets of optimal CNC performance as we delve into the Ultimate Checklist for CNC Maintenance. From preventive measures to troubleshooting tips, this resource ensures your CNC machinery operates at its peak efficiency.

The Crucial Role of CNC Maintenance

CNC machines are intricate systems comprising various components working in harmony. Neglecting any aspect of their upkeep can result in downtime, increased production costs, and compromised product quality. KES Machine LLC stresses the significance of a proactive approach to maintenance to prevent issues before they escalate. A well-executed maintenance plan ensures that CNC machines consistently deliver the precision and efficiency that manufacturers depend on.

The CNC Maintenance Checklist

Regular Cleaning and Lubrication:

Begin with the basics – cleanliness. Dust, debris, and accumulated residues can adversely affect the precision of CNC machines. Regularly clean the machine components, paying special attention to the tool changer, ball screws, and guide rails.

Lubrication is equally vital. Properly lubricate moving parts to minimize friction and reduce wear. KES Machine LLC recommends using lubricants specifically designed for CNC machines.

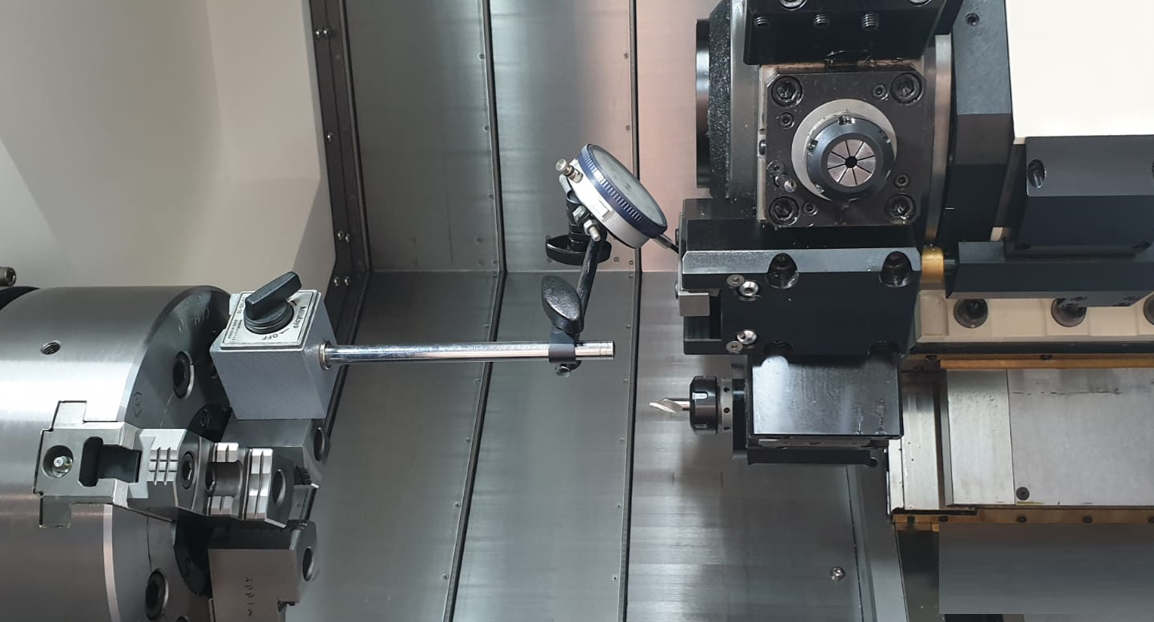

Inspecting and Calibrating Axis Alignment:

Periodically inspect and calibrate the alignment of the machine’s axes. Misaligned axes can lead to inaccuracies in the machined parts. KES Machine LLC employs advanced alignment tools to ensure the optimal performance of CNC machines.

Checking and Replacing Tooling:

Tools are the workhorses of CNC machining. Regularly inspect cutting tools for signs of wear and replace them promptly to maintain precision and prevent damage to the workpiece. KES Machine LLC experts emphasize the importance of using high-quality tools for optimal results.

Examining Electrical Components:

Thoroughly inspect electrical components, including wiring, connections, and circuitry. Address any issues promptly to avoid electrical failures that can disrupt production. KES Machine LLC employs skilled technicians to perform detailed electrical inspections as part of their maintenance services.

Updating Software and Firmware:

Keep CNC machine software and firmware up-to-date to benefit from the latest enhancements and security patches. KES Machine LLC emphasizes the importance of consulting with the machine manufacturer for compatible updates and patches.

Monitoring Coolant Systems:

CNC machines often use coolant systems to regulate temperature during machining processes. Regularly monitor coolant levels and quality. Clean or replace coolant as needed to prevent overheating and ensure optimal cutting conditions.

Conclusion

In the realm of CNC machining, maintenance is not just a routine but a commitment to precision and reliability. The ultimate CNC maintenance checklist outlined above, with insights from the experienced professionals at KES Machine LLC in the USA, serves as a comprehensive guide for ensuring the longevity and optimal performance of your CNC machines. By adhering to these practices, businesses can minimize downtime, reduce operational costs, and maximize the return on their CNC machine investments. Remember, a well-maintained CNC machine is a productive CNC machine.