High pressure ball valve are essential components in various industrial settings where the control and isolation of high-pressure fluids or gases are crucial. These valves offer several advantages over other valve types, making them a preferred choice in such demanding environments.

-

Reliable Sealing: High-pressure ball valves are designed with a spherical closure element, typically made of metal or ceramic, which provides excellent sealing performance. When the valve is in the closed position, this ball rotates to create a tight seal against the valve seat, minimizing the risk of leakage even at high pressures.

-

Quick Operation: One of the standout features of ball valves is their rapid quarter-turn operation. This allows for quick opening and closing, making them ideal for emergency shut-off applications. In high-pressure scenarios, the ability to respond swiftly to changing conditions is paramount.

-

Durability: These valves are built to withstand harsh conditions and maintain functionality over an extended period. Materials such as stainless steel or alloy make them corrosion-resistant and capable of handling high-pressure environments without deteriorating.

-

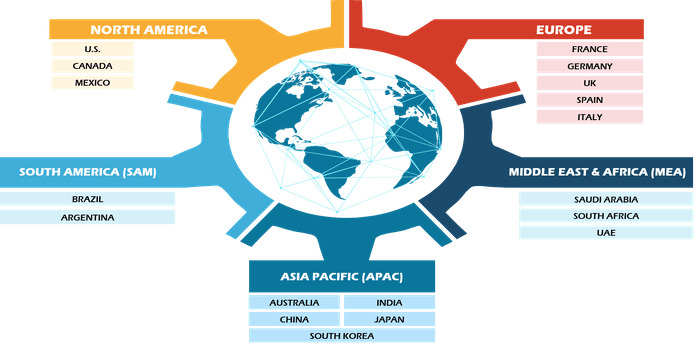

Versatility: High-pressure ball valves are versatile and can be used in a wide range of applications, including oil and gas pipelines, chemical processing, power generation, and more. Their adaptability makes them a preferred choice for various industries.

-

Low Maintenance: Due to their simple design and robust construction, high-pressure ball valves generally require minimal maintenance. This reduces downtime and operational costs, making them cost-effective in the long run.

-

Precise Control: While primarily used for on-off applications, high-pressure ball valves can also provide precise flow control when equipped with special trim options. This versatility allows them to handle various control requirements in high-pressure systems.

In comparison to gate valves or globe valves, High pressure ball valve excel in scenarios where fast response, reliable sealing, and durability are essential. However, it’s crucial to select the right type of valve based on the specific requirements of your application, as each valve type has its unique strengths and limitations. Consulting with valve experts and considering factors such as pressure ratings, flow rates, and fluid compatibility will help ensure the optimal choice for your high-pressure industrial needs.

For more information visit chinaoemvalve.